From September 4 to 6, the 2023 (20th) China International Chemical Exhibition, hosted by the China Petroleum and Chemical Industry Federation, the Chemical Industry Branch of the China Council for the Promotion of International Trade and the China Chemical Information Center, was held at the Shanghai New International Expo Center. The 38,000 square meters of exhibition area brought together more than 700 exhibitors, covering energy, petrochemicals, coal chemicals, basic chemical raw materials, special chemicals, new chemical materials, technology and equipment, packaging and storage and transportation logistics, safety and environmental protection, smart chemicals and intelligent manufacturing. Many new products, new technologies and new equipment are refreshing.

At the exhibition, overseas merchants showed great interest in some new products, stopped in front of the booths to ask the staff for information and inquire about product performance.

Shuttled through the various exhibition halls, the reporter's eyes were not only on the exquisite product samples, dazzling and colorful display boards, various equipment and realistic park sand table models on the booths, but also on the bright light display boards in the major special exhibition areas. The words "green", "low carbon" and "smart" frequently appeared.

The reporter learned that these keywords are exactly the information that major exhibitors want to convey to the audience most - under the background of slowing global economic growth, domestic economic recovery falling short of expectations, continued intensification of industrial competition and strengthening of the constraints of the dual carbon goals, China's chemical industry will focus on key elements such as greening, low carbonization and intelligence in structural adjustment and transformation and upgrading. And the real core fulcrum behind it is the all-round improvement of scientific and technological innovation capabilities.

"In the next 10 years, the chemical industry will face a new round of transformation cycle. The competitiveness of global chemical companies will be reshaped, and international leading chemical companies will turn to seek new core technological competitiveness. Chinese companies are no exception. Only through independent research and development, innovative development, and breakthroughs in core technologies and key products can we obtain new development opportunities." Huang Yinguo, CEO of the Consulting Division of China Chemical Information Center, put forward this view at the forum held at the same time, which resonated with the participants.

"The development of an enterprise must rely on technological innovation. Without technological innovation, the enterprise will have no source of power for development. Only innovation can solve the safety, environmental protection and low-carbon bottlenecks encountered in the development of an enterprise." Qiu Jinbiao, executive director and party secretary of Sinopec Jianghan Salt Chemical Hubei Co., Ltd., said in an interview. He introduced that the 30,000 tons/year bleaching powder concentrate process route independently developed by the company is 6 times the scale of the existing device. While the scale of the device is expanding, the company's energy conservation and emission reduction, cost reduction and efficiency improvement, safety and environmental protection, automation and intelligence levels have also been greatly improved due to the intensive production.

In the exhibition area of Shanghai Huayi Group, a blue display board with "isotope" written on it aroused the curiosity of the audience. On-site staff Ye Zhanhong introduced that stable isotope technology is the most dynamic emerging field in the chemical industry. Isotope markers as tracers have been widely used in medical diagnosis, life sciences, agricultural research, environmental sciences, analytical testing, semiconductor chips and other fields. At present, Shanghai Chemical Research Institute Co., Ltd. has made breakthroughs in a series of key technologies for the enrichment of stable isotope raw materials and the synthesis of their markers, breaking the foreign monopoly.

On the booth of the State Energy Group, there are samples of packaging boxes, plastic bags, etc., which look the same as ordinary polyolefin plastic products, but they are made of coal-based biodegradable material polyglycolic acid. "This product is fully biodegradable and highly biocompatible, and has good mechanical and barrier properties. The key is that it can be completely degraded in natural environments such as soil and seawater, and does not require special composting conditions." Wang Chao, the company's sales director, told reporters.

It is reported that the company's polyglycolic acid process route uses independent intellectual property technology. Compared with the production of traditional polyolefin plastics, the raw material coal consumption of polyglycolic acid per ton of product can be reduced by about 50%, carbon dioxide emissions can be reduced by about 65%, industrial added value can be increased by 2 to 3 times, and the production cost is close to that of ordinary plastics, which has strong market competitiveness. The company's 50,000 tons/year production unit that has been put into production is currently in full production.

In addition to a variety of new products, the exhibition also showcased the technological innovation and new progress of green, low-carbon and intelligent upgrading of equipment.

In the smart chemical and intelligent manufacturing exhibition area, Jiangsu Tom Intelligent Equipment Co., Ltd. brought 4 new packaging equipment. Among them, the three-row push filling machine capping machine, compared with traditional filling equipment, not only has good stability, strong reliability and high precision, but also improves the filling efficiency by 1/3 and reduces energy consumption by 10%. "This is mainly due to the company's strong investment in independent innovation capabilities. At present, the company has more than 40 national invention patents, more than 260 practical patents, and hundreds of new products independently designed and developed." Liu Yang, deputy general manager of the Chemical Packaging Division of Jiangsu Tom Group, told reporters, "In order to better adapt to the needs of intelligent upgrading of the chemical industry, we have also established a special software company to provide customers with customized intelligent filling solutions to help companies reduce costs, improve quality and increase efficiency. Despite the severe economic situation this year, the company's sales in August hit a record high."

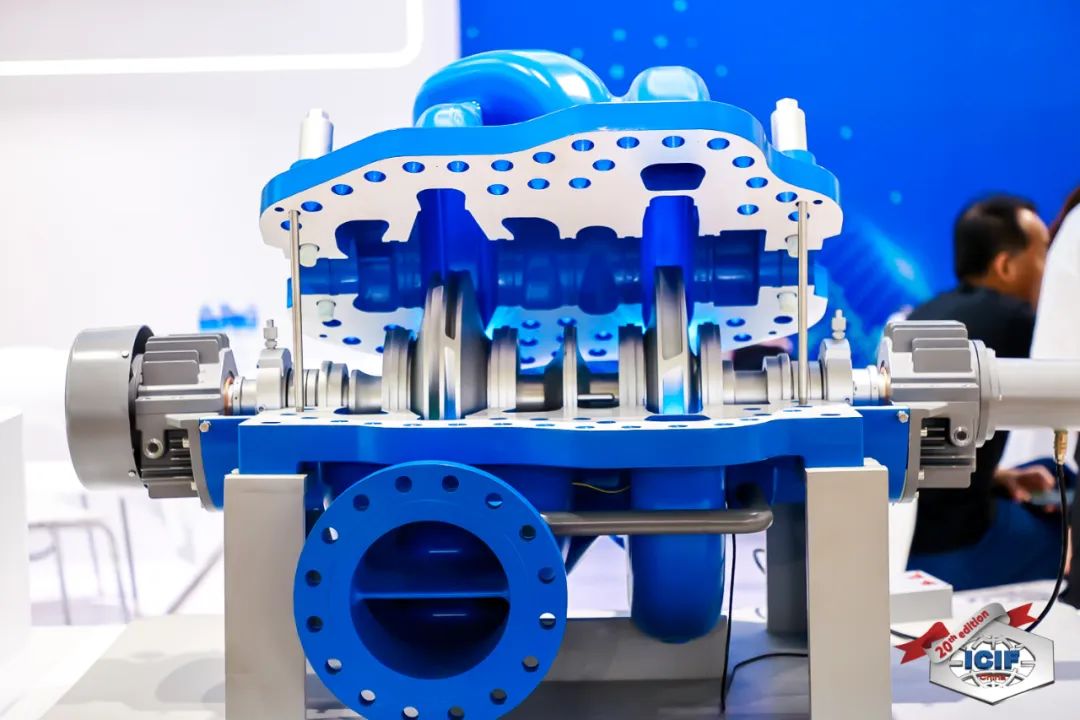

Pumps are the most commonly used equipment in the fluid chemical industry. However, the horizontal split-center two-stage oil pump displayed on the booth of Danai Pump Industry Co., Ltd. is different. This is a new product specially launched by the company for storage oil depots. It can achieve large flow and high head oil transportation with only two-stage impellers. The design parameters are completely customized according to the storage field. It can all achieve high-efficiency zone operation, and it occupies a small space and is easy to maintain. Liu Xiaoyu, the company's brand manager, said that Danai Pump Industry has a 70-year development history. The key to the company's ability to maintain its leading position in the industry development lies in continuous technological innovation. Innovation not only improves the company's production efficiency, but also brings considerable economic benefits to customers.

At the Air Products booth, in addition to the display of traditional business, the company also launched a low-carbon transformation plan. In the past year, the company announced major capital investment in support of energy transformation projects and pledged to invest $11 billion in clean energy transformation pilot projects. The person in charge of the company said that in fiscal 2022, 70% of the company's R&D expenses will be invested in research related to sustainable development and energy transformation. In the past three years, more than 80 new patents have been applied for in the fields of sustainable development and energy transformation. These technologies can help customers reduce 86 million tons of carbon dioxide emissions each year.

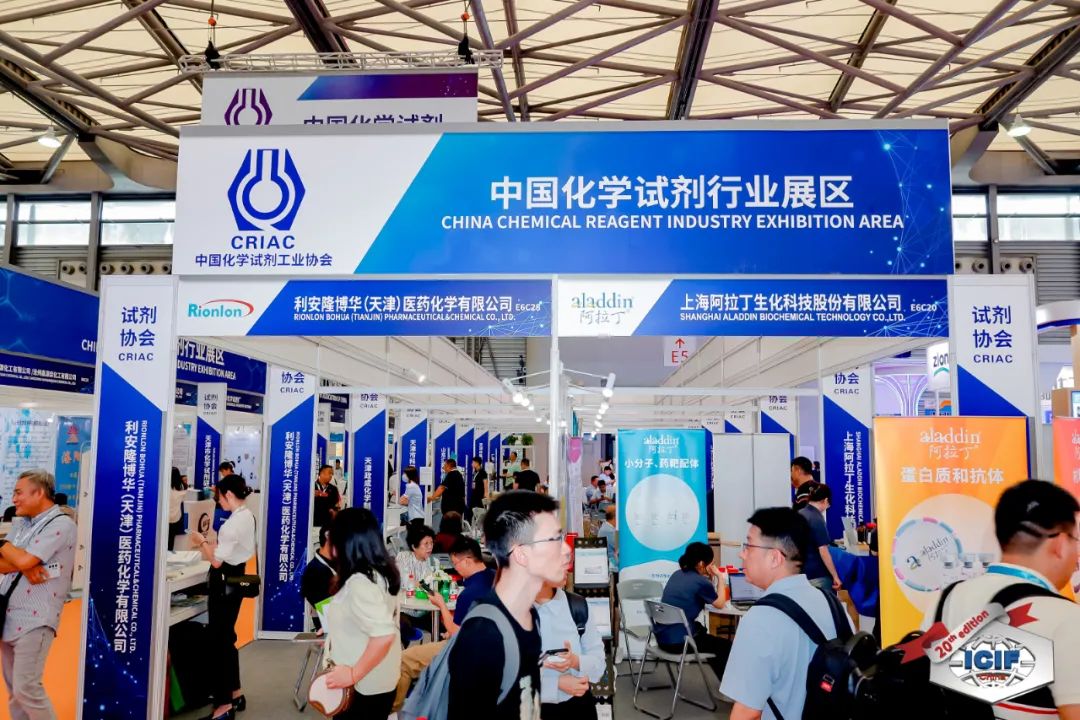

The exhibition also set up a special area for chemical reagents. More than 30 chemical reagent manufacturers concentrated on displaying new products and new technologies. Ji Zhe, deputy secretary-general of the China Chemical Reagent Industry Association, told reporters: "Although chemical reagents have a small output, they are of many varieties and high quality requirements. They are a strategic resource that serves scientific and technological research and development and various fields of the national economy. They are indispensable in promoting scientific research and technological innovation in my country. Therefore, the industry needs to increase its R&D efforts in solving common technologies and replacing imports. At the same time, there is also a need for innovative measures suitable for the development of the industry in management systems such as storage, transportation, and safety production permits."

After three days of the exhibition, the reporter felt most deeply that the concept of independent innovation has been deeply rooted in people's hearts. This is not only forced by the international situation, but also required by the development of enterprises themselves. Whether it is a large-scale state-owned enterprise or a small and medium-sized private enterprise, everyone has a consensus - there is no way out for price involution, industrial structure adjustment is imminent, and only by focusing on innovation can there be a future.

For more information about the China International Chemical Exhibition, you can click on the official website: www.icif.cn

Pages you might like

Pages you might like

Exhibitions you may be interested in

Exhibitions you may be interested in

Latest information

Latest information

Follow official account

Follow official account

Online support

Online support

鄂ICP备2022017323号

鄂ICP备2022017323号

鄂公网安备 42018502006493

鄂公网安备 42018502006493

Launch Exhibition

Launch Exhibition

Release information

Release information

Today's topic

Today's topic